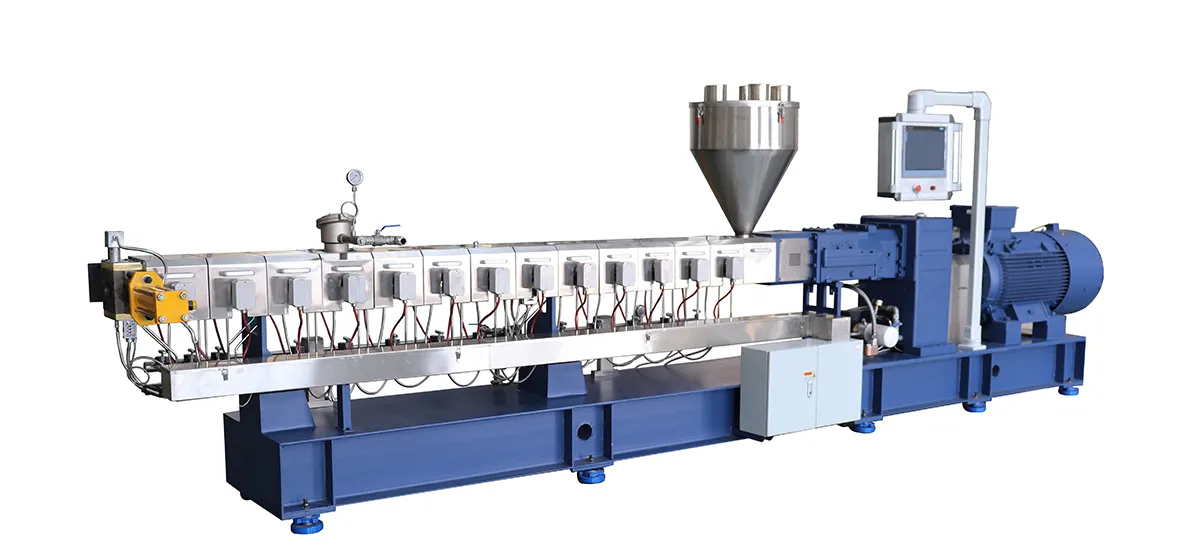

Twin-screw extruders are an important and indispensable tool in the modern plastics manufacturing industry. With the ability to improve product quality, improve production efficiency and minimize raw material waste, they have become the first choice for Vietnamese plastic manufacturing enterprises.

1. What is a Twin-Screw Extruder?

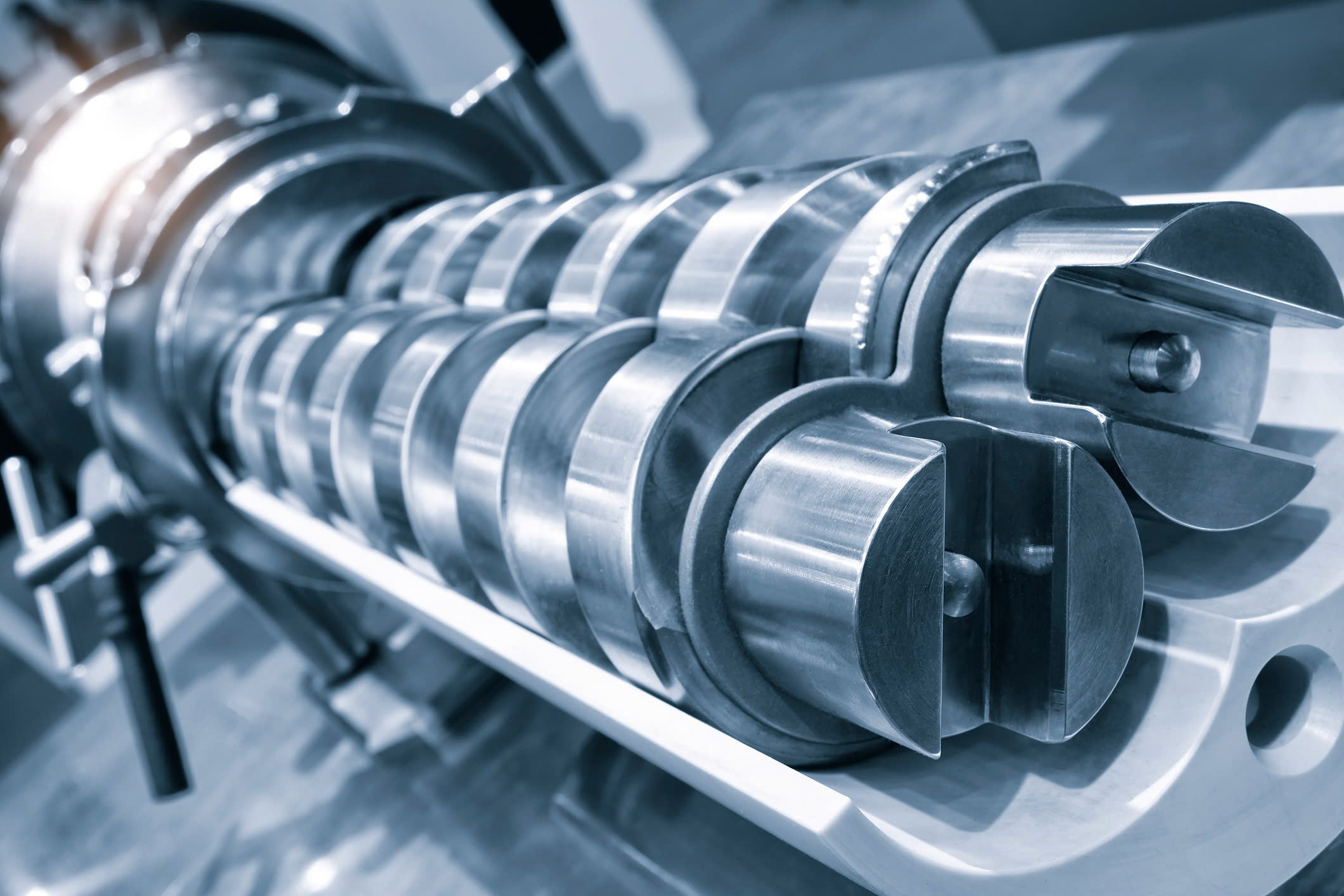

A twin-screw extruder is a type of industrial machinery used to process and shape plastics. The special feature of this machine is that it uses two screws rotating in opposite directions, helping the mixing, extrusion and plastic molding process to take place more effectively than single-screw extruders.

2. Structure and Operating Principle

A twin-screw extruder is made up of two parallel screws, rotating in opposite directions in an extrusion housing. When operating, plastic materials are fed into the feed hopper and move along the length of the screw. Through friction and pressure, the raw materials are melted, mixed, and extruded through a mold to create the final product.

3. Advantages of Twin Screw Extruder

High mixing efficiency

The twin-screw extruder is capable of mixing raw material components, including different types of plastics, additives, and colors, evenly. This helps improve product uniformity and enhance the quality of the final product.

Flexibility in Production

With the twin-screw design, the machine can adjust the speed, temperature, and pressure according to the specific requirements of each type of product. This helps optimize the production process and meet the diverse needs of the market.

Saving raw materials and energy

The twin-screw extruder is capable of minimizing raw material waste thanks to the efficient mixing and extrusion process. At the same time, the flexible adjustment of technical parameters helps save energy and reduce production costs.

Wide range of applications

It is widely used in the production of plastic products such as pipes, sheets, films, plastic granules, and many other types of engineering plastic products. The wide range of applications of the machine helps businesses optimize the production process, meeting the strict requirements of customers.

4. Applications of Twin Screw Extruders in Plastic Production

Twin screw extruders are the ideal choice for complex production processes that require high product quality consistency. Typical application areas include:

- Compounding: The machine is often used to mix and create plastic compounds by combining base resins with additives, colorants, heat stabilizers, antioxidants, and reinforcing agents such as glass fibers. This process helps improve the physical properties, color, and durability of the final product.

- Mixing and coloring: In plastic production, coloring and mixing of resins with other additives is very important. Twin screw extruders allow the mixing process to be carried out evenly and efficiently, ensuring the quality of the output product.

- Plastic recycling: Twin screw extruders are widely used in plastic recycling. They are capable of processing waste plastics and used plastics by recycling them into new products or secondary materials.

- Pelletizing: Twin screw extruders can produce plastic pellets that are uniform in size and shape, which are used as raw materials for subsequent manufacturing processes such as injection molding or molding.

- Production of special plastic products: Twin screw extruders are capable of controlling the temperature, pressure and residence time of the raw materials during the extrusion process, allowing the production of special plastic products such as engineering plastics, heat-resistant plastics, conductive plastics, and composite plastics.

- Application in biomaterial production: Twin screw extruders are also used to produce biomaterials and biodegradable plastics, such as plastics used in food packaging that are completely biodegradable in the natural environment.

5. Conclusion

Twin screw extruders are one of the important equipment to improve product quality and optimize the plastic production process. With the ability to mix raw materials effectively, save energy, and have a wide range of applications in the production of plastic products, it has proven to be an indispensable role in the modern plastic industry. For plastic manufacturing enterprises, the use of this machine not only helps improve production efficiency but also ensures product quality to meet increasingly stringent market requirements.

Read more news from Dai A Industry:

𝐃𝐀𝐈 𝐀 𝐈𝐍𝐃𝐔𝐒𝐓𝐑𝐘 𝐉𝐒𝐂

🌐Linkedin: https://www.linkedin.com/company/67721636/

☎ What’sApp: +84 936 123 984

📧 Email: info@daiaplastic.com