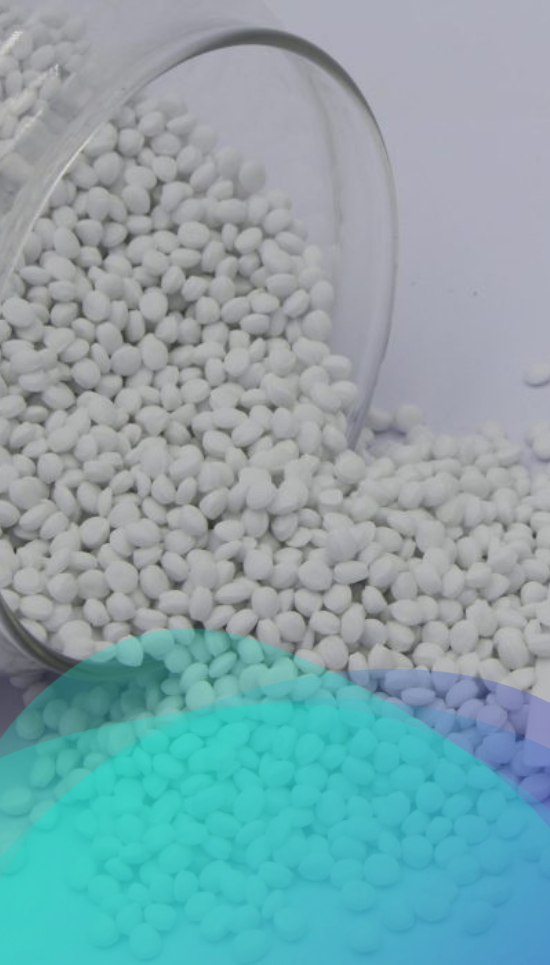

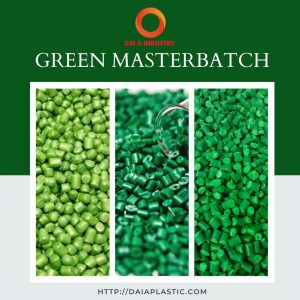

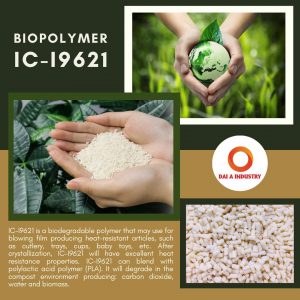

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch

Color Masterbatch