Plastic injection moulding is an extremely versatile, highly efficient and reliable method of producing complex plastic parts and components. It is one of the most widely used manufacturing processes for mass producing plastic components.

6 major advantages of Plastic Injection Molding

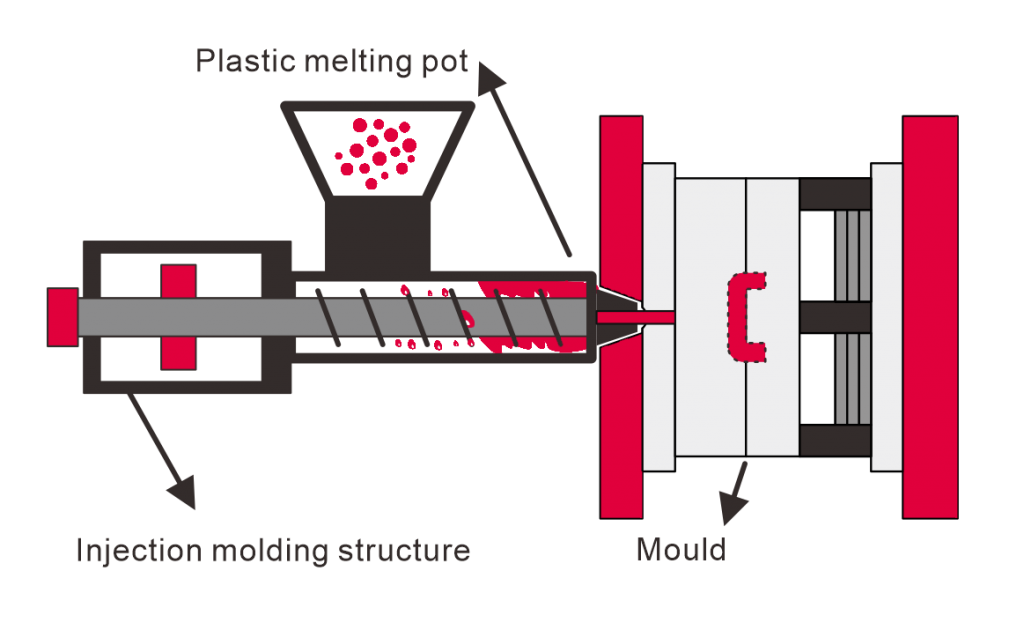

A versatile manufacturing process involves melting plastic pellets or powder and forcing the liquid plastic under pressure into a precision-engineered mould tool cavity. The molten plastic then cools and solidifies to precisely match the shape of the mould cavity. There are many advantages of using injection moulding for manufacturing plastic parts and components:

1. Production speed

Plastic injection moulding is inherently a fast production method. Production cycle times can be as short as a few seconds depending upon the component being moulded.

2. Highly efficient process

The plastic injection moulding process consumes little time and this allows more parts to be manufactured from a single mould. The high production output rate makes plastic injection moulding more cost effective and efficient.

3. Minimal waste

The plastic injection moulding process is extremely efficient as very little raw material is scrapped or wasted. Essentially, there is little to no waste that is produced – this ensures the use of raw materials can be optimised and costs minimised.

4. Complex design

Injection moulding can produce extremely complex parts with a high degree of accuracy, uniformity and repeatability. Plastic injection moulding uses a higher injection pressure to create the part than other types of moulding. Due to the high pressure used, intricate designs can be created.

5. Flexibility

While the speed, accuracy and cost efficiency of plastic injection moulding are huge benefits, the flexibility of the manufacturing method is remarkably important. There also is flexibility to alter part design, especially at the beginning of the process.

Choosing the right material and colour for a project are two of the essential factors in creating plastic parts. Due to the wide variety of both, the possibilities are almost endless. Advances in plastic polymers over recent years have contributed to the development of a large selection of materials to choose from.

6. Cost effective manufacturing

Plastic injection moulding allows for automated, mass production on a very cost-effective scale. The majority of the process is controlled by computerised equipment and machinery. Automation helps to reduce manufacturing costs, as overheads can be significantly reduced. As a result, this means the overall cost of manufacturing parts can be fully optimised.