Introduction:

Plastics and polymers are inherently low in thermal and electrical conductivity. For this reason applications that require conductive properties, which could also benefit from the use of polymer components because of their light weight, high strength/weight ratio, easy moldability, etc, can not take advantage of this desirable material. Research is in progress on inherently conductive polymers, and some polymers with reasonable conductivity values are commercially available. However, at the present time admixing inert, conductive fillers into non-conductive polymers remains a very effective and economical way to produce an electrically or thermally conductive polymer component.

Carbon and Graphite as Conductive Fillers: Graphite and carbon offer the benefit of low density and cost when compared to metallic substances used for the same function. Graphite and carbon also have an advantage in that they are typically inert and compatible with most if not all polymer systems. Carbon materials provide electrical conduction through the pi bonding system that exists between adjacent carbon atoms in the carbon/graphite structure. Thermal conduction is affected by overlapping sigma bonds which are part of the same molecular bonding system. Regardless of whether or not the conduction is thermal or electrical, electrons provide the pathway for energy transfer.

Many carbons, and especially graphite, have thermal and electrical conductivities many orders of magnitude higher than most polymers or plastics. However it is not necessarily an easy task to significantly increase the conductivity of plastic by a simple addition of conductive carbon. The problem becomes one of “dispersion”, “pathway development”, or “continuity” using the conductor as the energy conduit through the polymer. If a conductor is dispersed through a non-conductive medium one possible configuration is a composite of conductive particles wrapped in insulative polymer. This configuration would result in an article that is no more conductive than the pure polymer. The key to creating a conductive polymer is the development of a continuous pathway of interconnected conductive particles through the polymer.

The photomicrograph on the left is an epoxy resin containing 200-mesh synthetic graphite. Although the individual graphite particles are highly conductive it is doubtful that any improvement in the bulk conductivity of the polymer will be realized. Close examination of the micrograph shows that the particles show only limited interconnectivity. Compounding with addition of finer graphite particles would help provide pathways between the larger particles resulting in better conductive continuity of the filler.

The micrograph below illustrates the improved interconnectivity realized when using 20-micrometer graphite with the same epoxy. The closer proximity of the conductive particles is apparent.

Generally, conductive continuity can be improved by reducing the particle size of the graphite powder. In applications where coarser particles are a requirement the addition of a small percentage of finer particles to the mix will significantly improved electrical and thermal continuity by providing conductive pathways between the coarser filler particles.

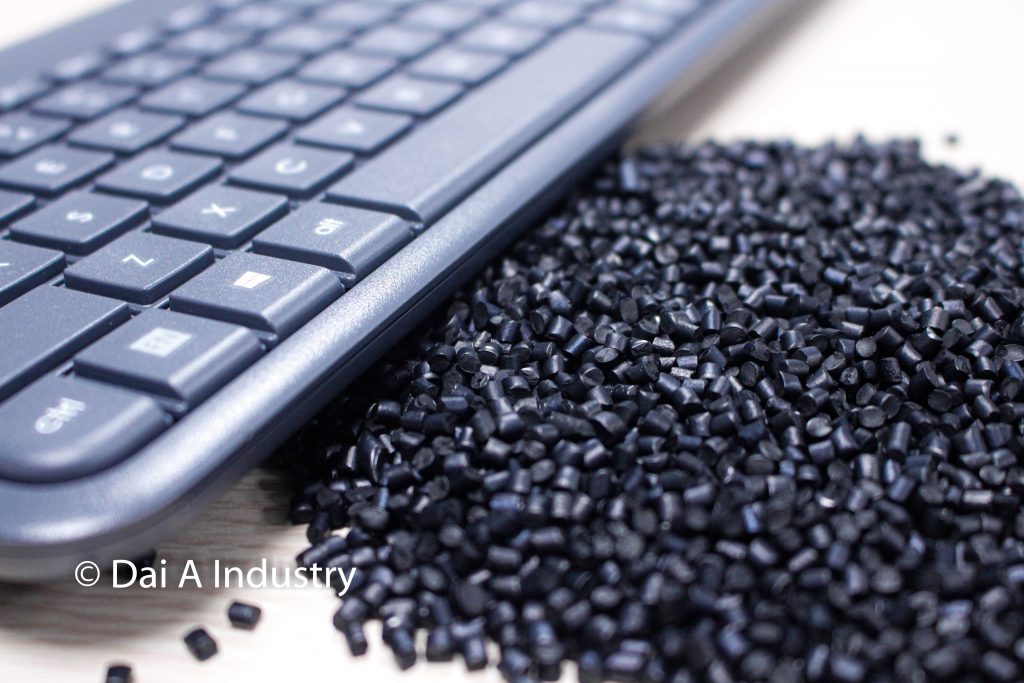

Contact Us: Dai A Industry Joint Stock Company can provide you with Plastic compound PP, HIPS, ABS … used for injection molding, casting film… capable of conducting electricity.