In recent years, the use of masterbatch for plastic production has become a “trend” emerging as a key technical method. This is an innovative solution to improve production efficiency as well as its sustainability.

2. Elevate plastic production with advanced material solutions

Today, masterbatch has become an “indispensable” material in many plastic processing methods, specifically:

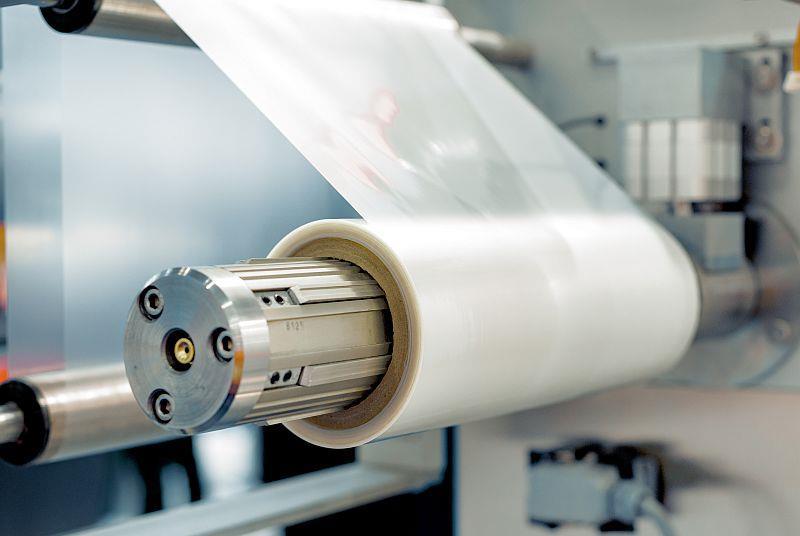

2.1. Film blowing and lamination

Film blowing & lamination is a widely used process in the plastics industry to produce films and sheets. Because it gives the final product excellent uniformity in length and width, it is especially popular in the packaging industry.

Masterbatch is used in blown film technology to improve hardness, control heat, increase turbidity… At the same time, this is also a solution to effectively cut production costs.

Furthermore, blockage in blown film is the most common phenomenon during polyethylene and polypropylene film processing. Therefore, plastic manufacturers tend to use lubricating and anti-blocking masterbatch to solve this problem.

2.2. Nonwoven fabric production

Because it is made from calcium carbonate powder (CaCO3), plastic resin and other special additives, masterbatch is one of the most effective material solutions for nonwoven fabric production.

Applying this material gives the final product a number of benefits such as: The product has a natural white color, improves the material texture creating a soft fabric feel, enhances thermal conductivity and mechanical strength. , environmentally friendly.

2.3. Injection molding

Masterbatch when mixed with base plastics such as PP, PE, PS, ABS… is considered the perfect solution for the production of household items such as furniture, boxes, containers, bottles, jars, basket,… through injection molding method. The final product created from the masterbatch mixture will have good thermal conductivity, better impact resistance, more flexible hardness and less shrinkage.

However, each product requires a precise formula for each production line and will be carefully considered depending on each customer’s specific requirements.

You can see more at:

Masterbatch – Sustainable solution in plastic production (Part 3)