In recent years, calcium carbonate is a versatile material, used by most businesses as a filler in the plastic industry. In this article, Dai A will reveal 4 reasons why calcium carbonate is widely used in the plastic industry.

Do you know plastic fillers from Calcium Carbonate?

CaCO3 is a compound with the chemical formula CaCO3. This substance is commonly found as limestone all over the world. According to scientists’ estimates, about 5% of the earth’s crust is CaCO3, which exists in various forms of compounds. Most of the CaCO3 used in industry is mined from quarries.

After being exploited and undergoing preliminary treatment, CaCO3 is divided into 2 types: fine CaCO3 (Ground calcium carbonate – GCC) and precipitated CaCO3 (precipitated calcium carbonate – PCC).

On the market today, CaCO3 GCC is the most important filler being used in many industries, especially as a plastic additive compound. This filler is produced by crushing raw limestone into small particles, mostly in powder form, which are then graded based on their size.

Plastic filler from Calcium carbonate is an additive used to increase the elasticity, viscosity and heat resistance of plastics. Calcium carbonate is commonly used in the manufacture of plastic products, such as bags, bottles, tubes, toys and many others. It is also used in the production of paper, cosmetics, and food. Calcium carbonate can be synthesized from limestone or from natural white lime minerals.

Why do plastic manufacturers prefer to use Calcium carbonate as plastic filler?

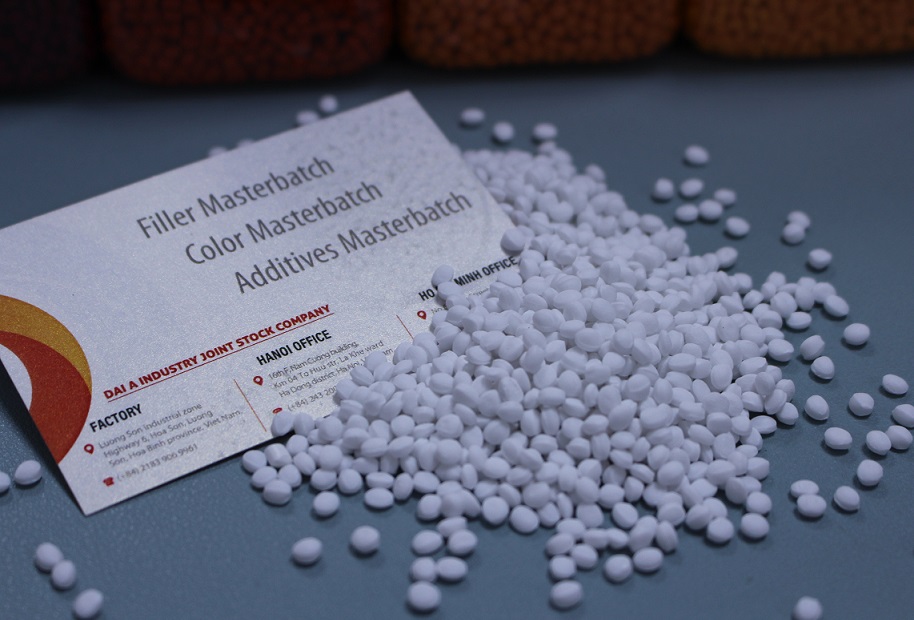

Calcium carbonate is widely used in the plastics industry as a plastic filler, usually in the form of white granules. Plastic filler, also known as masterbatch, which is mainly composed of CaCO3 and base resin, is preferred for the following 4 reasons:

1. Calcium carbonate is abundant and easy to obtain

Cheaper and more commonly known as a common material, calcium carbonate can be used as a filler in the production of plastics to improve product stiffness and stability. It is an ideal substitute for other fillers, such as BaSO4.

2. Improve the physical properties of plastic

Calcium carbonate is an additive used in plastic products to improve their physical properties, including strength, impact resistance, hardness, and resistance to high temperatures. It is also used to reduce the toughness of plastic products and aid in plastic processing.

The use of calcium carbonate in the production of plastics helps to increase the mechanical properties, which has a positive effect on the stability of the plastic. This will help plastic products have a longer life, resulting in longer functional use.

3. Bring great economic benefits

As mentioned above, calcium carbonate is a cheap material that is available in the market, the use of calcium carbonate can reduce production costs and lead to more competitive prices for plastic products. Many plastic enterprises have noticed and calcium carbonate has become an attractive option with the function of additive in plastic production.

4. Safe and environmentally friendly

With the ability to biodegrade, calcium carbonate is not harmful to the environment. In addition, calcium carbonate also has the features of fireproof, waterproof and soundproof,…And this is an ideal material in the plastic industry now and in the future.

Calcium carbonate is a widely used material in the plastics industry due to its availability, low cost and positive impact on the properties of plastic products. It enhances the hardness and durability of plastic products, which reduces production costs and improves product performance. In addition, calcium carbonate is also used in other fields such as papermaking, paint, printing ink, washing powder, moisture-proof agent and food. Its use has increased rapidly in recent years and it will likely continue to be the preferred choice of plastic manufacturers in the future.